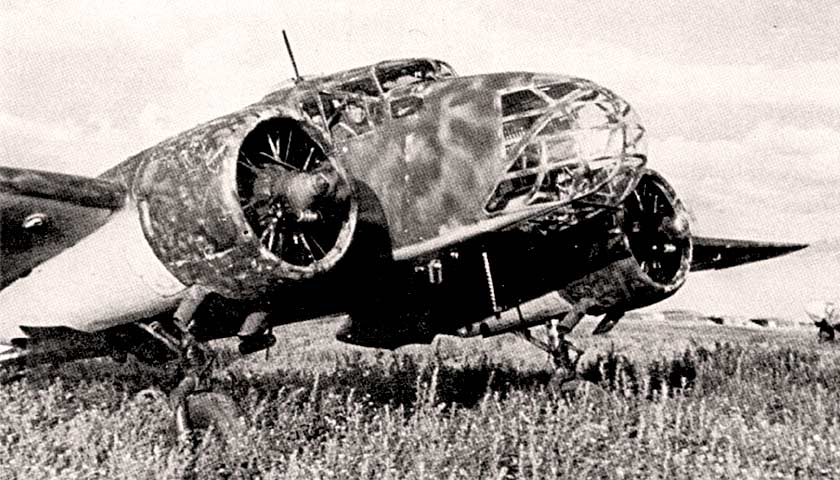

Then the time came to “lathe” the wheels. Theoretically, such things, for the “purity of the genre”, should be strictly dosed. I mean turned parts from a blank glued from many layers of cardboard. This is a forced technological measure, like a wire and a transparent film for glazing cabs.

I think that wheels for aircraft can be made in this way without violating the “cardboard” technology. This issue and other is worth discussing so as not to shy away from cardboard technology.

So the wheels. Here an old drill entered into business — the second and last “stronghold” of my “machine park” in that time.

There was a lot of dust! Like in real production. It is a real horror! I did not expect this. But the wheels are good, that is, they liked to me.

And here another nuance arose. I turned up the wheel on an axle made of a two-millimetre screw with sawn-off head and two pairs of nut-washer. But 2 mm for the wheel axle is too much. I had to later insert a sleeve into this hole, a tube twisted from office paper 0.1 mm thick. It turned out very well. The sleeve tightly had sat in the wheel and on the axle. Beats and skews are minimal, so that the model rolls itself under the slightest slope.

Here the wheel putted on the axle as yet without a sleeve. But in the photo below — already with the sleeve.

To be continued…