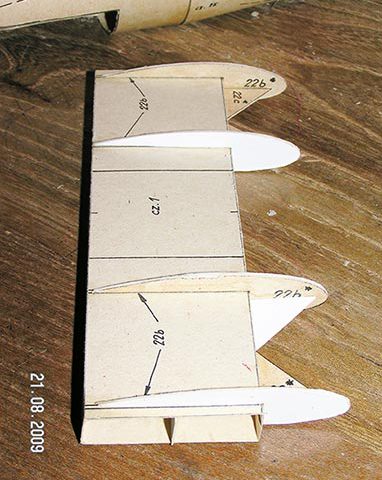

Step by step the matter has come to the supporting structure of the center section.

It turned out to be simple and logical, as the youth says: Respect to the author!

The only thing that seemed to me to be rather weak was the box of the center section, and I inserted one spar there – the middle one. After that, the box stopped moving back and forth and it fixed its own transverse shape.

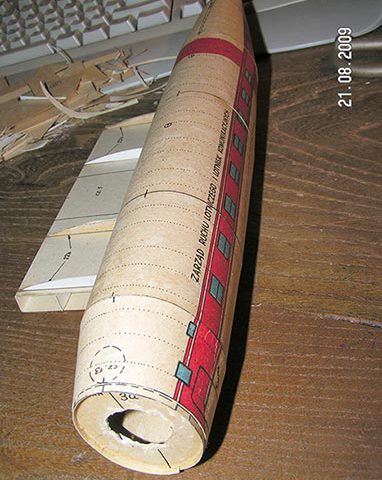

By the way, anyone who has ever encountered the welding process of sheet metal structures cannot but notice the analogy with gluing cardboard parts. I mean that cardboard can also be connected end to end and apply the same principles of assembly of the structure as in the “metal” assembly. And even the strand of glue seems like a weld bead. (It is the engineer who woke up from my past life).

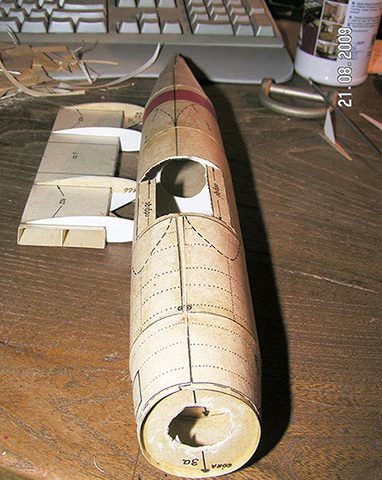

In the next photo, the cutout for the supporting box of the center section is already cut. It was necessary to do what had to be done from the very beginning at this point. Maintain continuous operational control of the accuracy of each model part.

But, you understand me: twenty-plus years I was out of card modeling. My hands forgot small fine work. It’s need to recover and remember how to make paper models and what tools I need to use.

It turned out to be crooked, but quite acceptable for the “first time”.

To be continued…