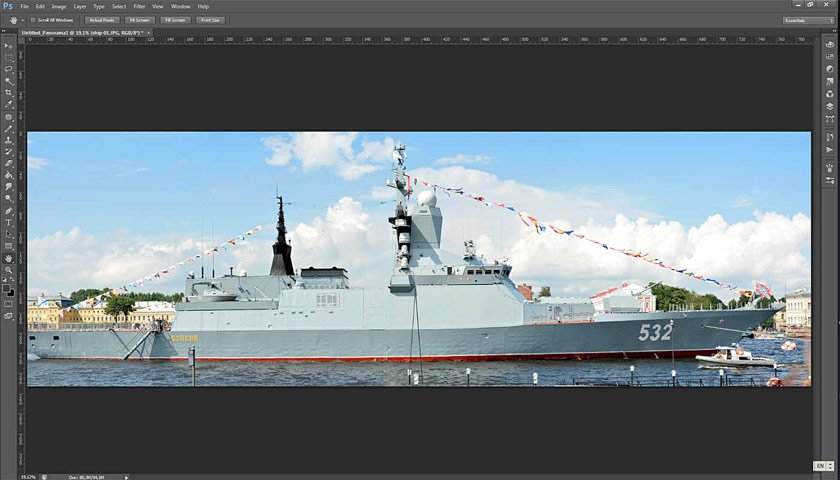

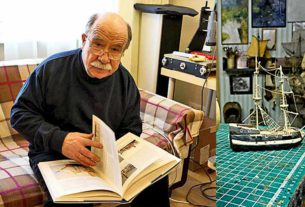

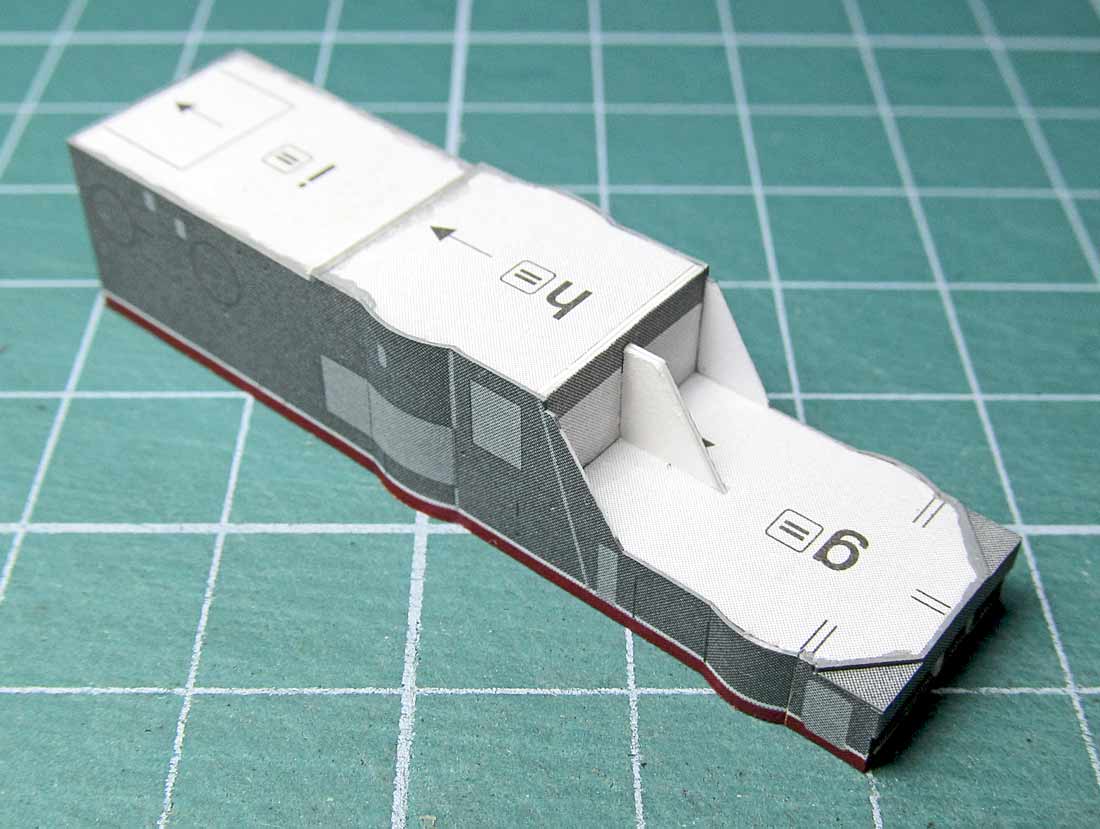

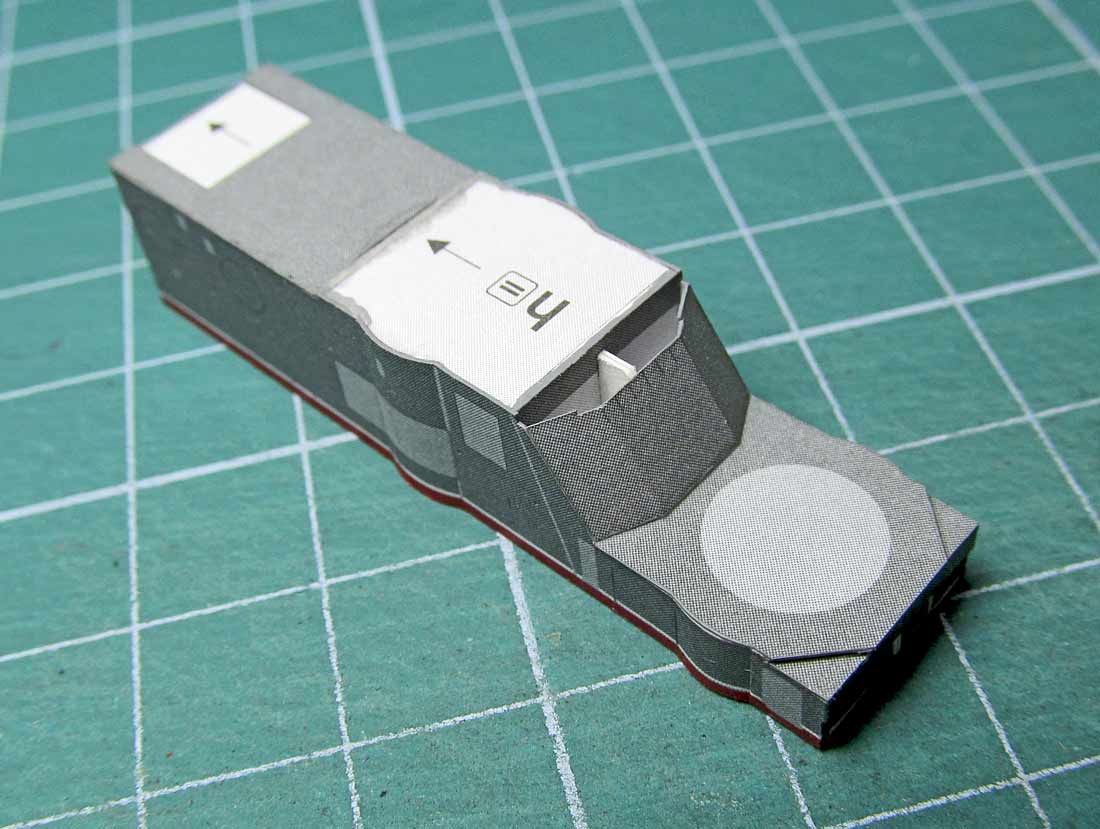

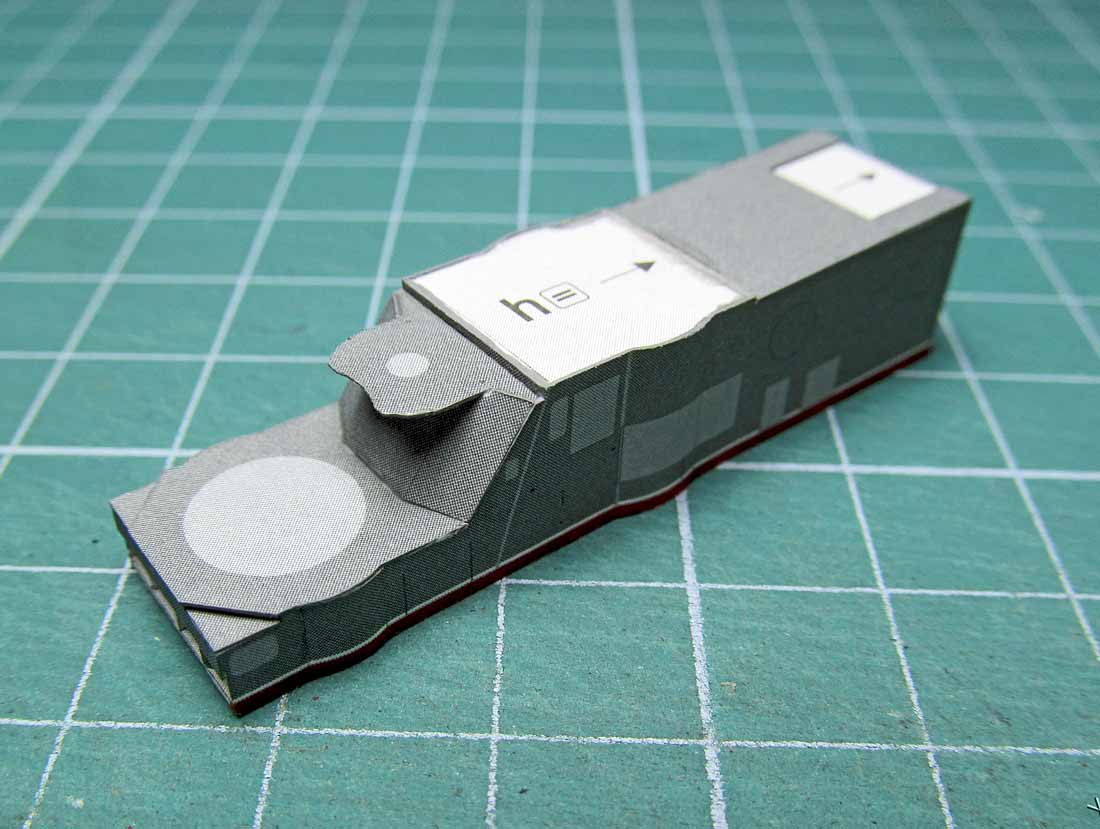

I am continuing to review the construction of the Mukha-class hydrofoil. The construction of the ship’s superstructure continues.

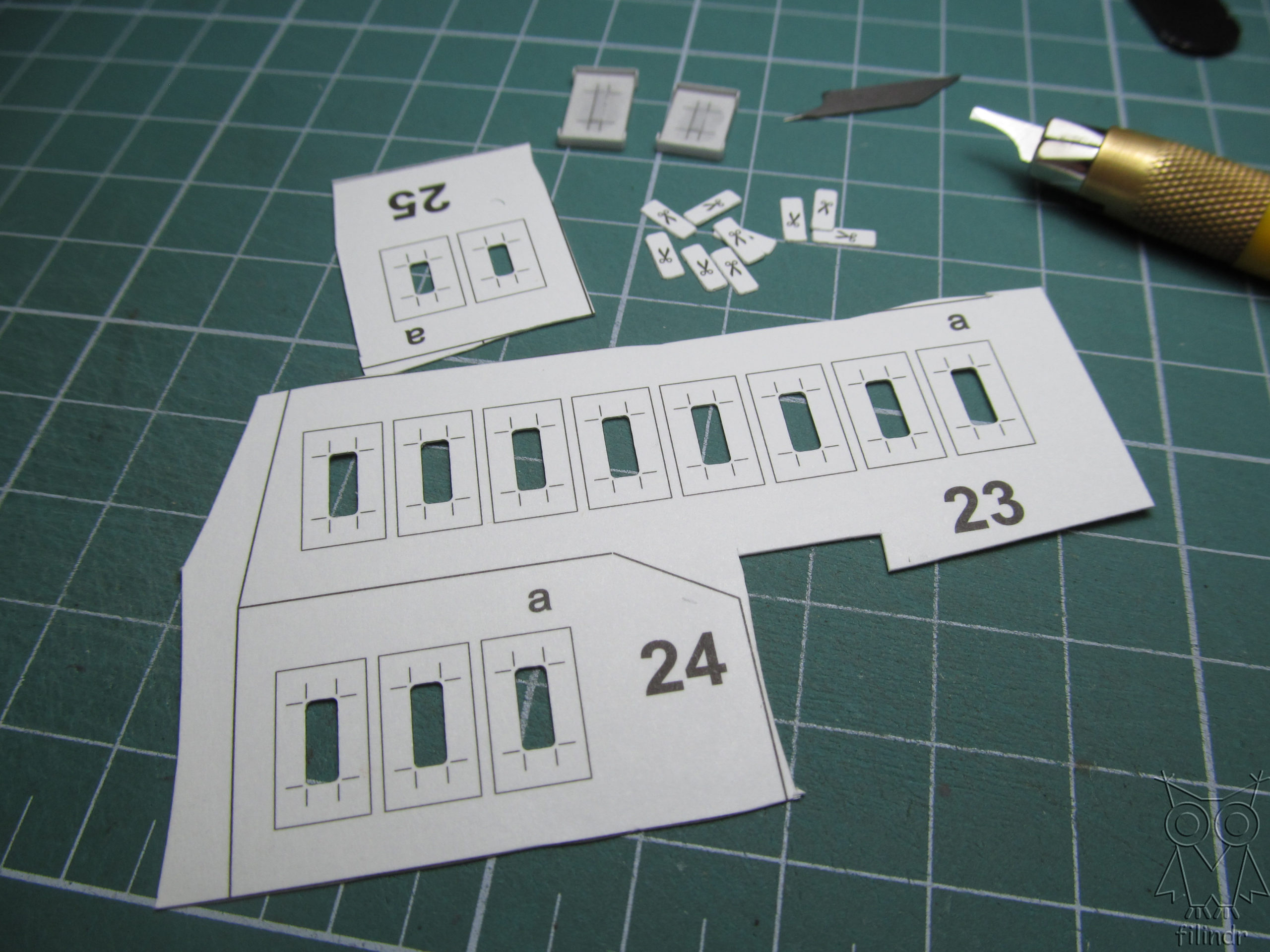

Superstructure of the second tier.

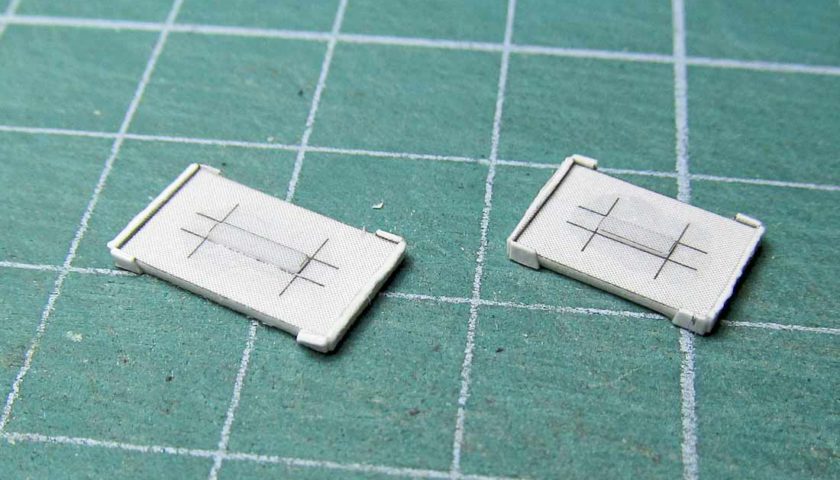

Now it’s the turn of making doors. There are quite a lot of doors and Filindr, as a true master of his craft, develops the technological process of making doors. As a result, all the doors are the same and very realistic, since Filindr came up with the process of stamping the doors.

Let’s take a closer look at the door production technology. First Filindr made a stamp. The main details – the base and the stamp itself, he impregnated with superglue. The parts have acquired the strength of plastic.

Then the flanges are glued to center the workpiece. They must be cut in height to the thickness of the workpiece so that you can press from above with the plane of an ordinary metal ruler:

Then the door creases frames are cut with holes in the middle.

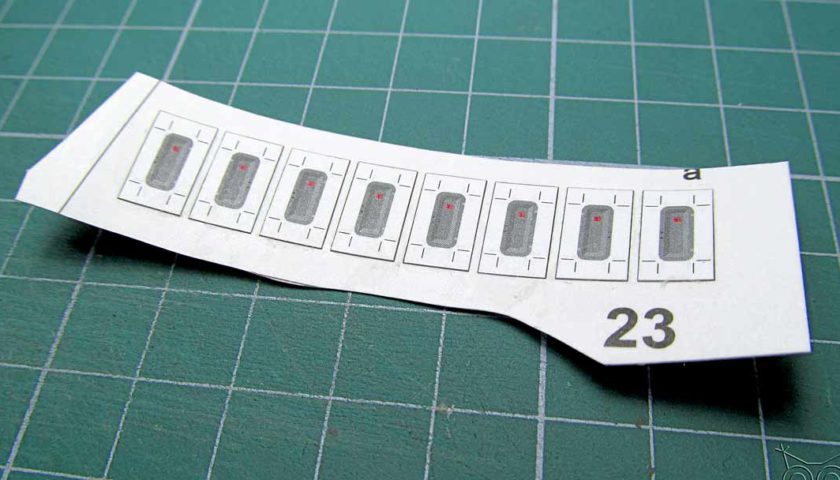

Blanks with doors are glued to them. Then PVA glue is applied along the edge of the hole in the frame and the workpiece is placed in the stamp with the door down. A load is placed on top and the edges of the door are squeezed down. The door itself remains in the middle upper part of the stamp.

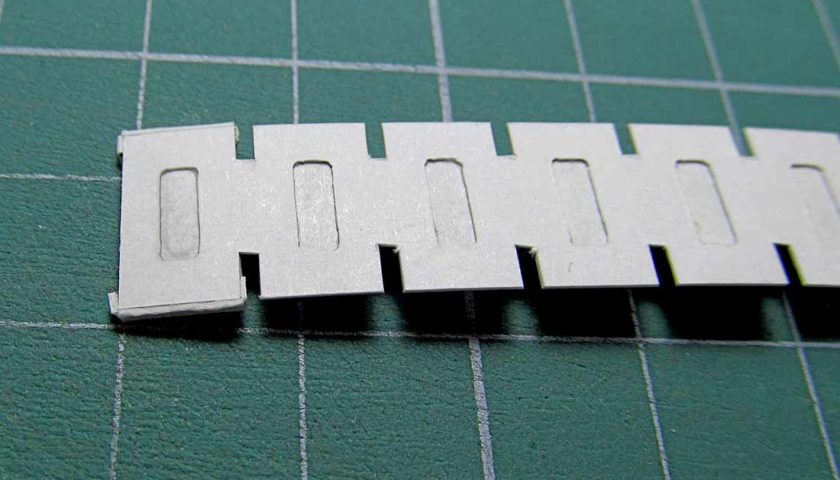

After the glue dries, the door keeps the shape obtained by stamping. For the convenience of work, the door frames and the doors themselves were left in a unified tape.

Now we need to make door hinges.

Then the door hinges are glued to the door, then the ends of the door are tinted, and the door is ready. It remains only to make the handles for closing the doors.

The doors are hung on the superstructure.

Other parts are also placed on the superstructure.

For handles, Filindr also came up with a simple and efficient manufacturing process for handles.

Using a soldered piece of brass, in which rectangles are cut to the size of the handles, he punches the handles from copper wire with an awl, pressing the blanks into the corner.

Then he cuts the pieces to size by pressing the knife against the side faces of the piece of brass.

Here’s what happened as a result of this interesting work.

To be continue…