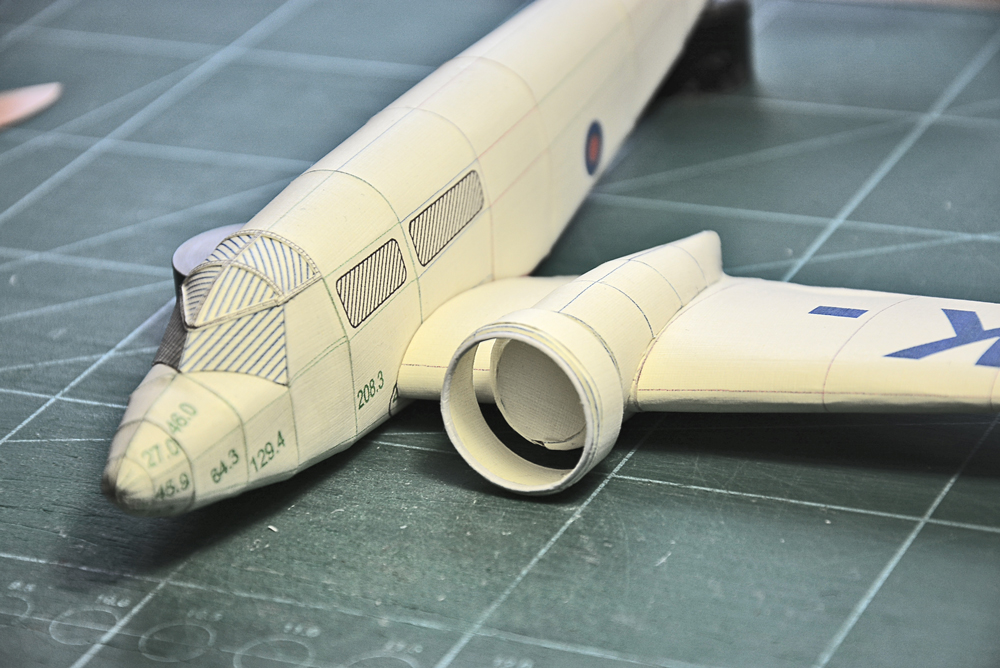

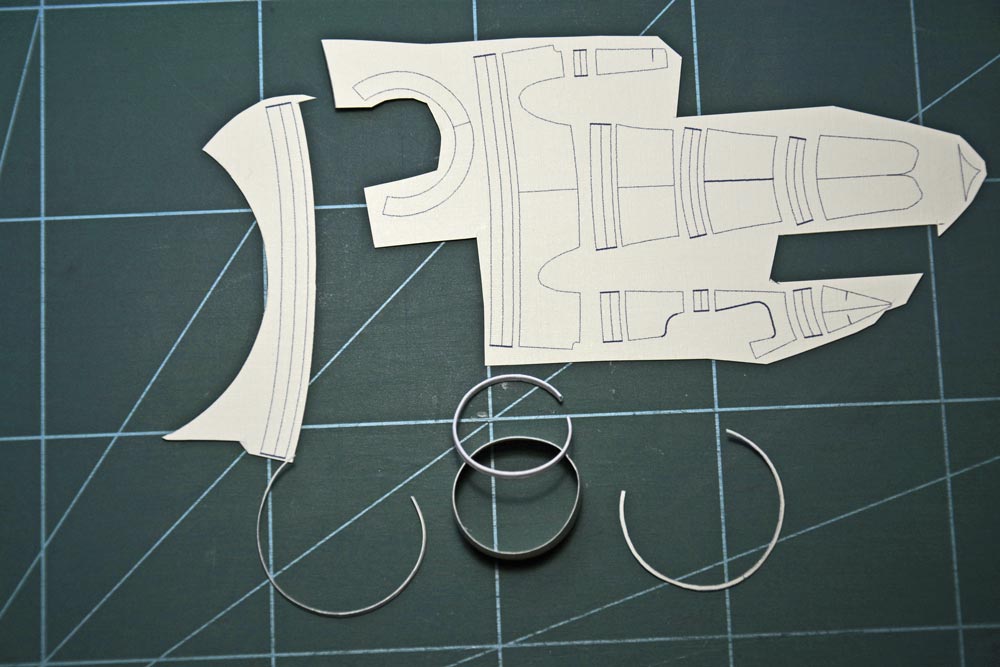

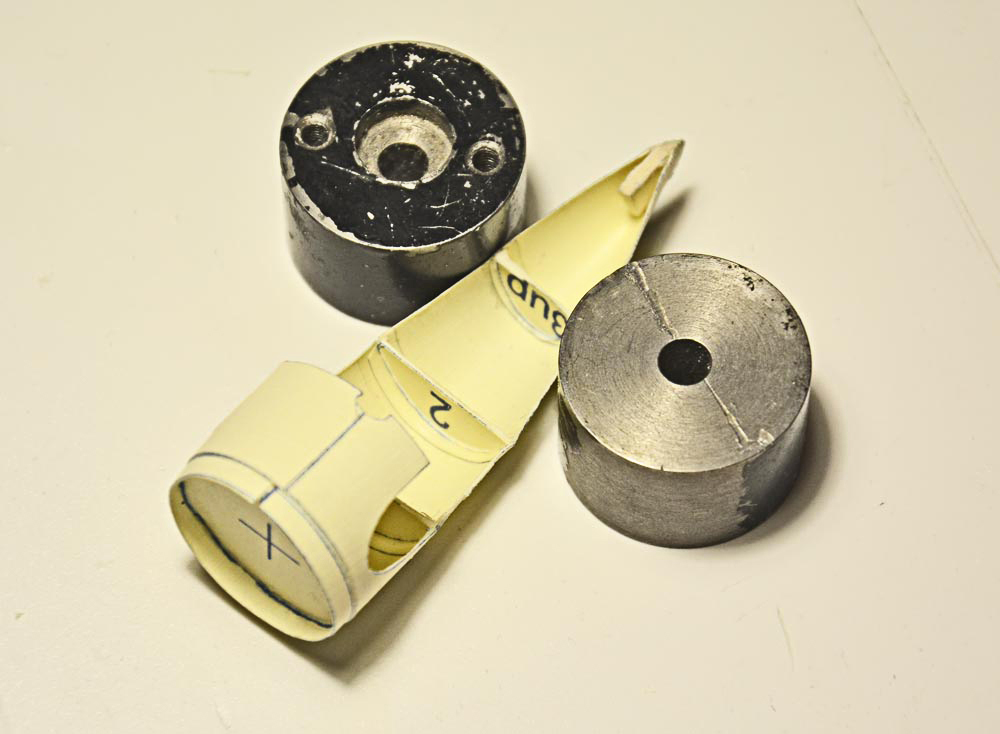

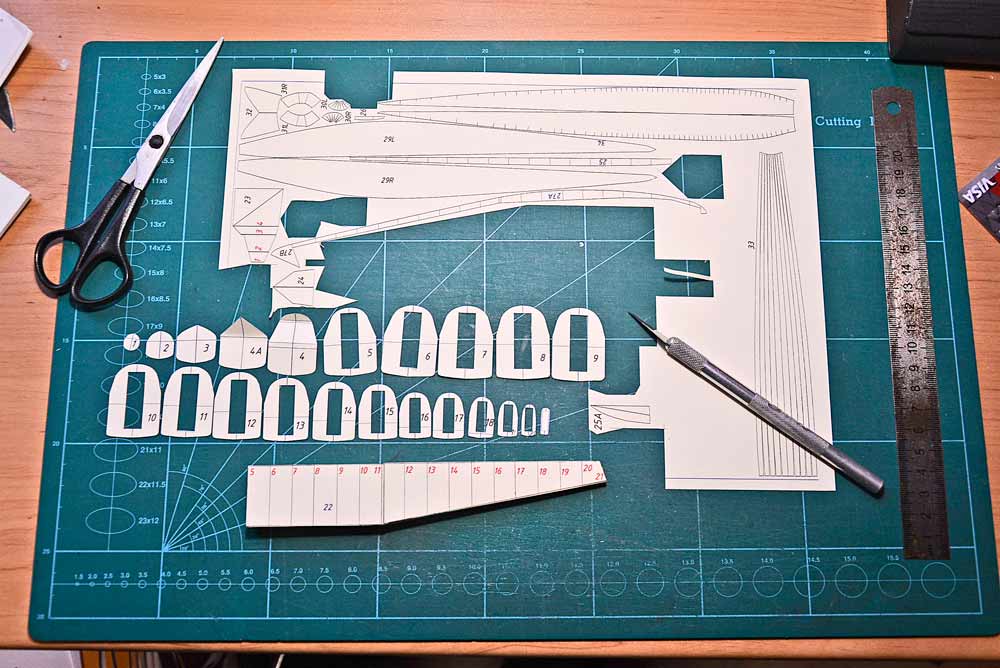

I assembled these designs using the traditional method from rings. However, here I was once again convinced of the need to come up with a solution for large-scale joints of parts.

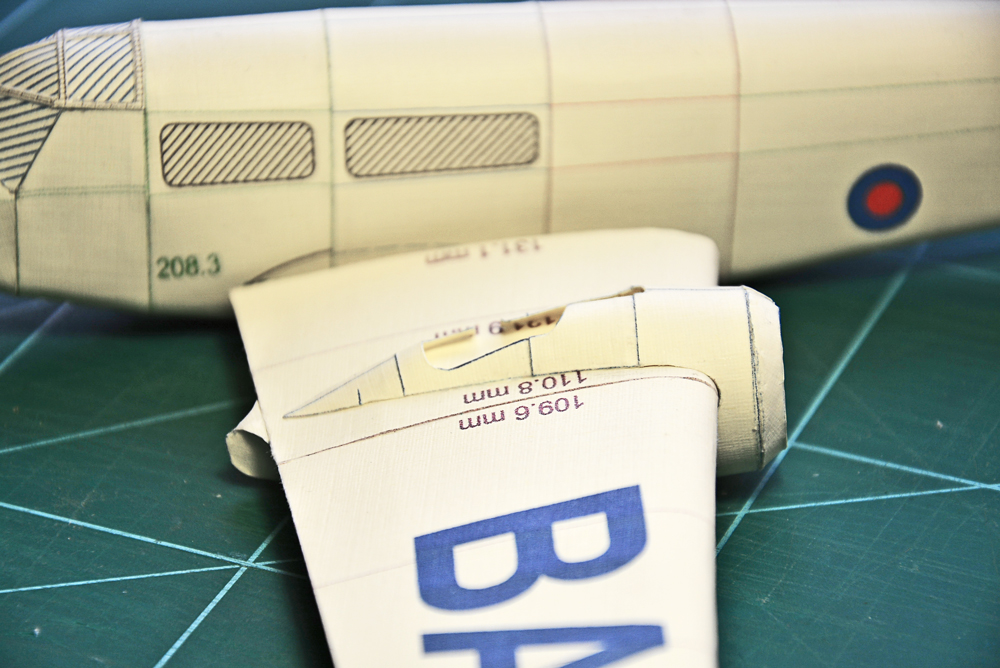

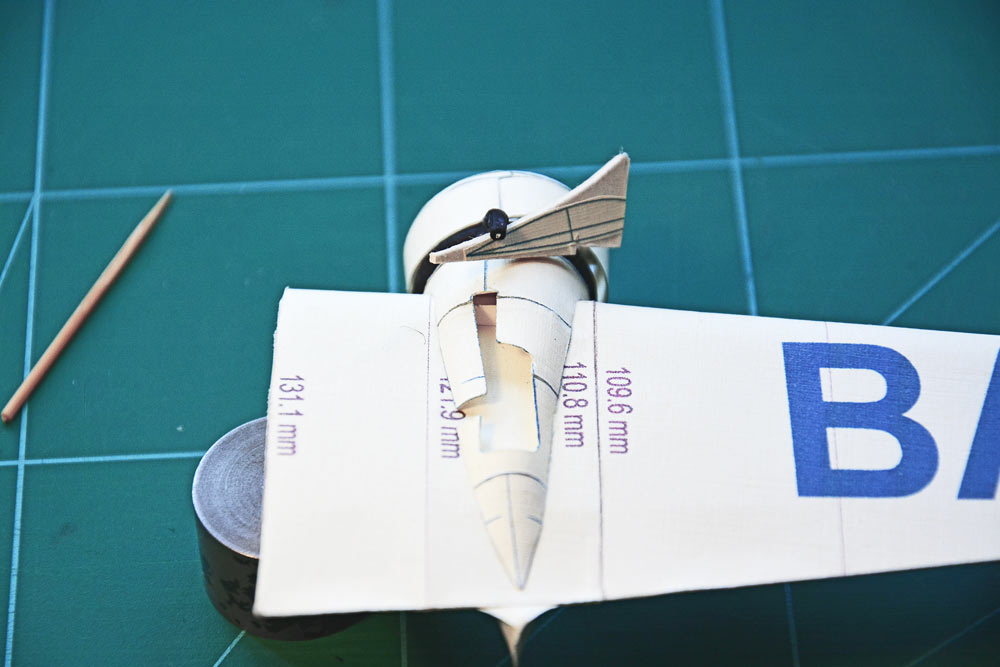

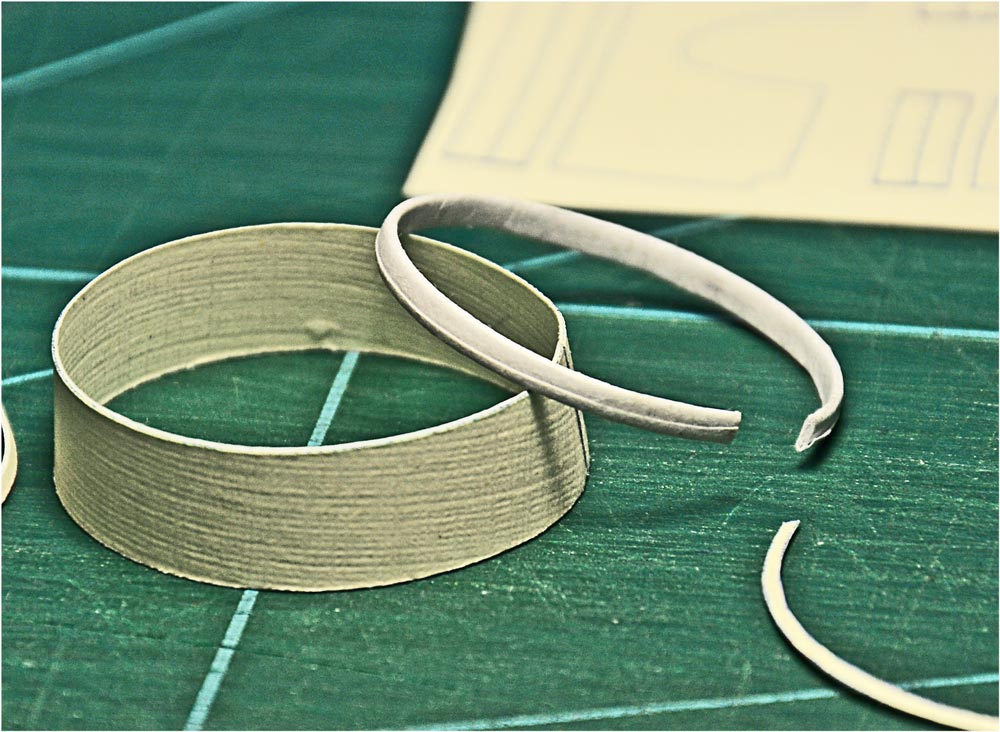

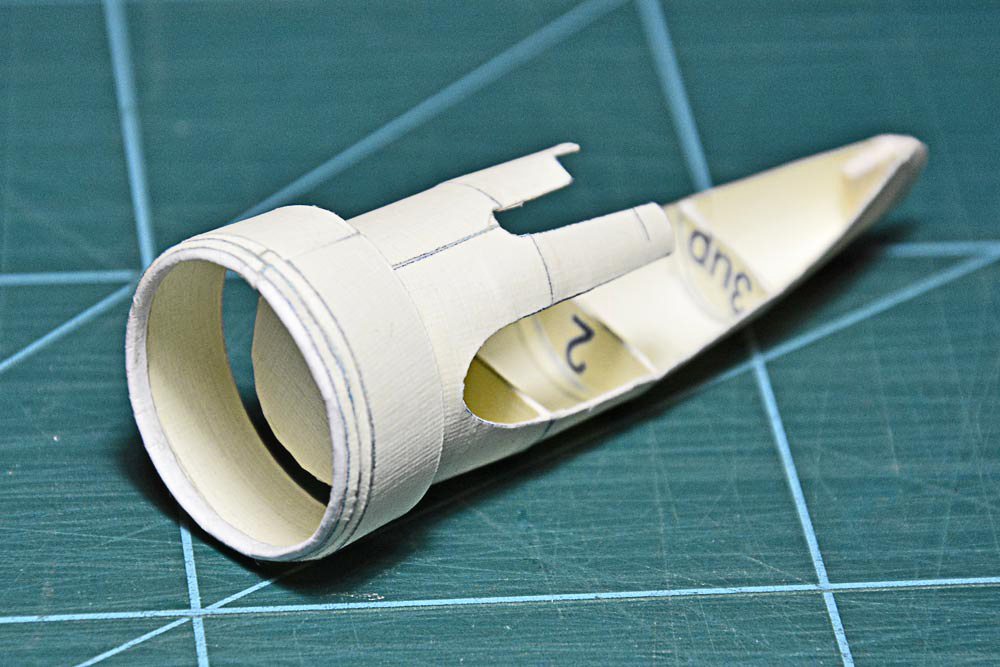

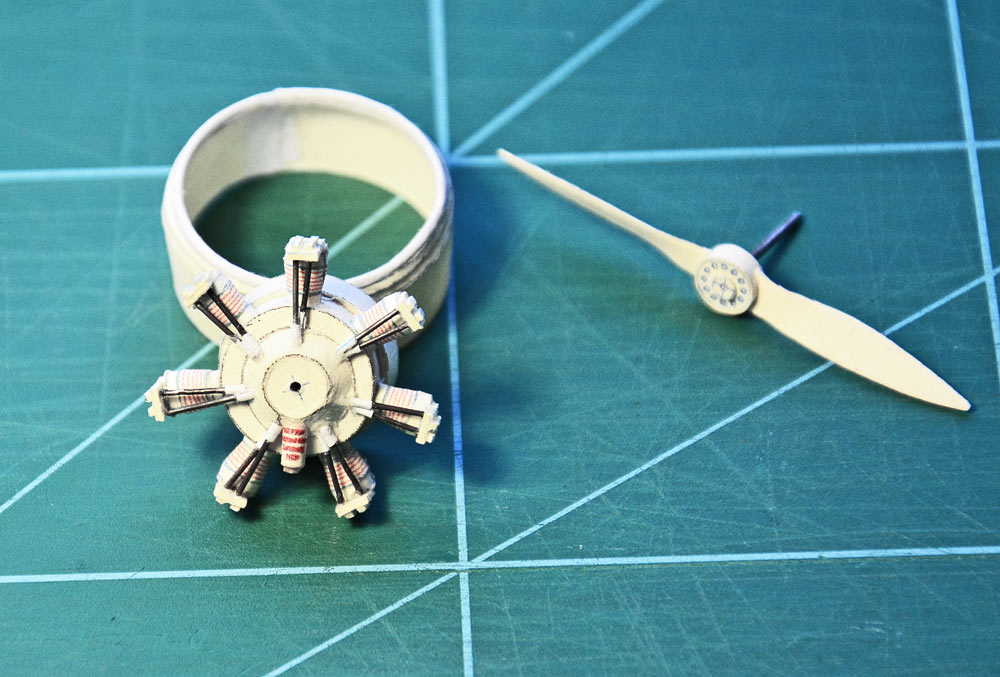

The second issue, which has long been in the queue to be addressed, is the leading edge of the engine hood. Usually, the front hood ring is simply made with a free edge. On real planes, there was always a special profile there. The metal sheet from which the hood ring was made would not have held the shape without reinforcement in this place.

I realized that I needed to make a similar construction. So far, it hasn’t looked very well. I need to refine this element more. So far, it turned out like this.

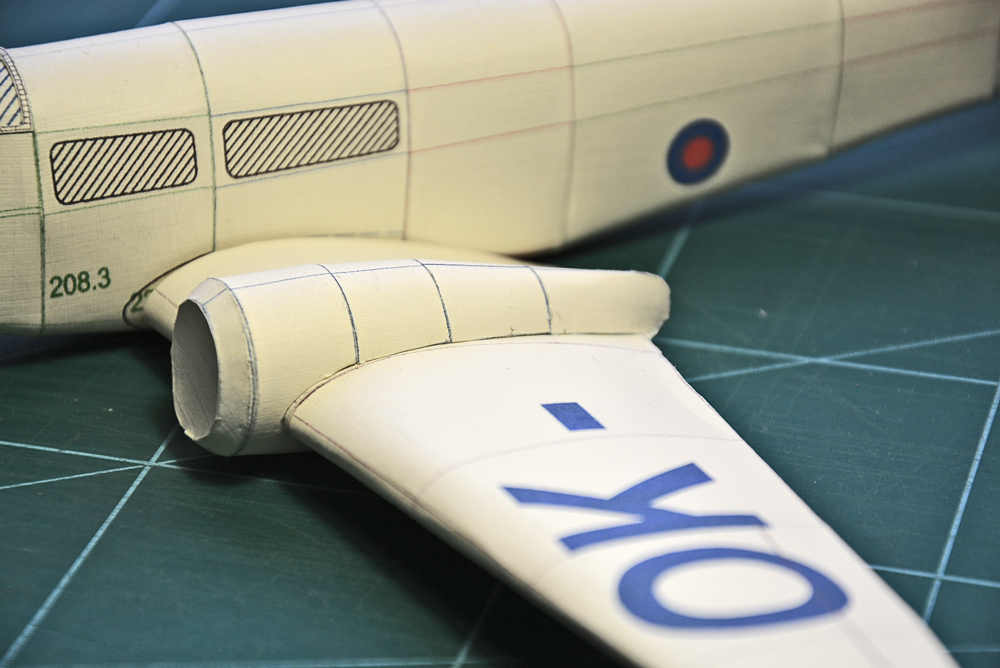

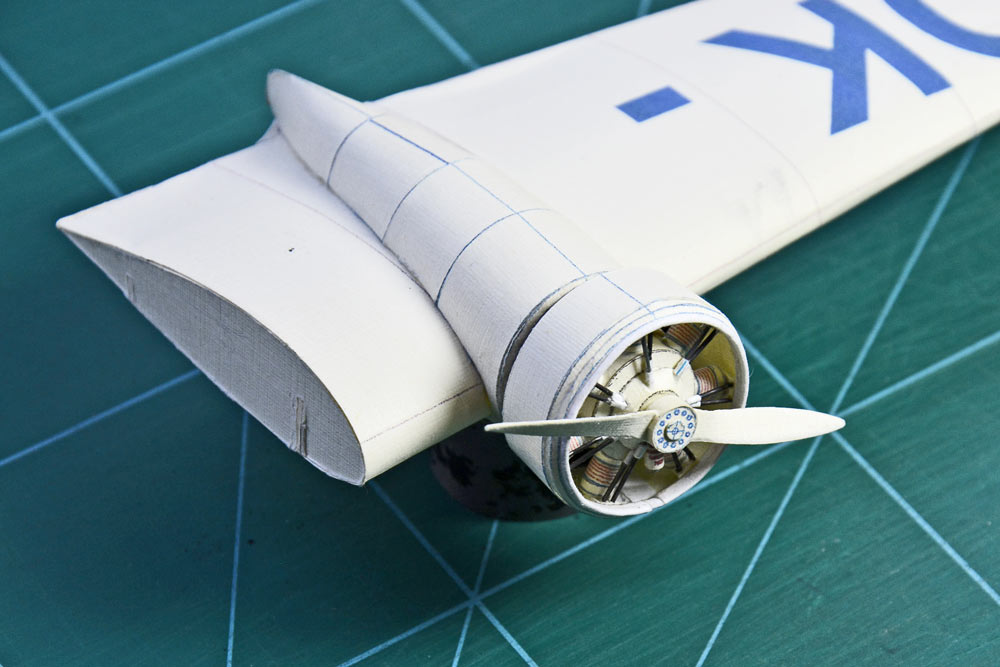

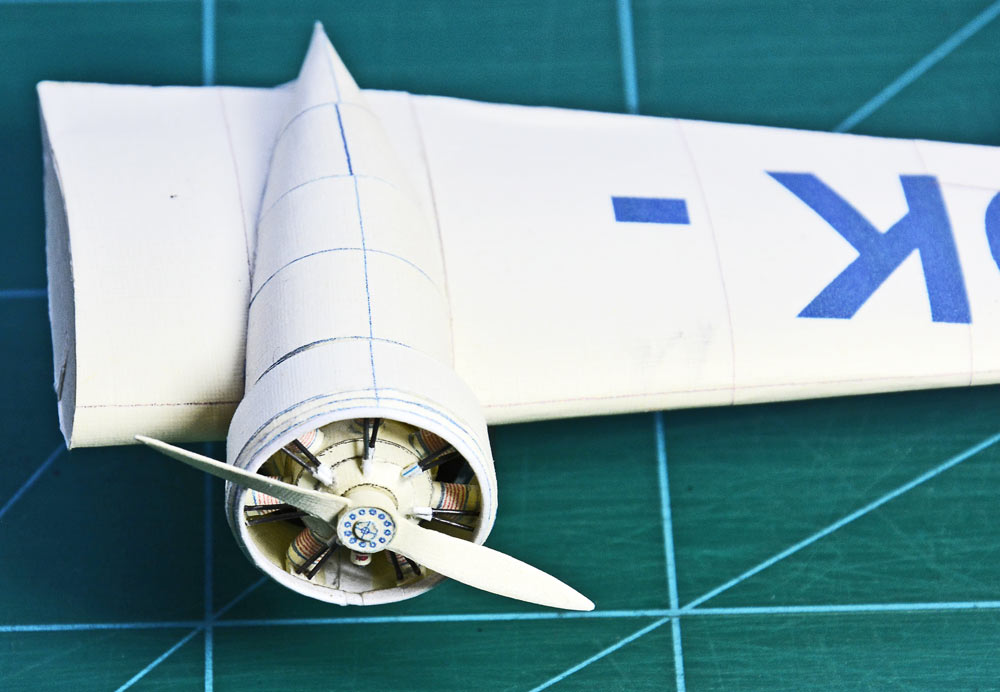

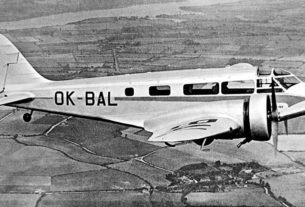

The engine nacelle caused no problems. Everything is understandable here. It turned out quite well. However, I have not made another important detail that is on the prototype. This is the fairing of the engine nacelle, in the place where it connects to the wing. This part is very complex for paper. How to do it, I have to think over specially.

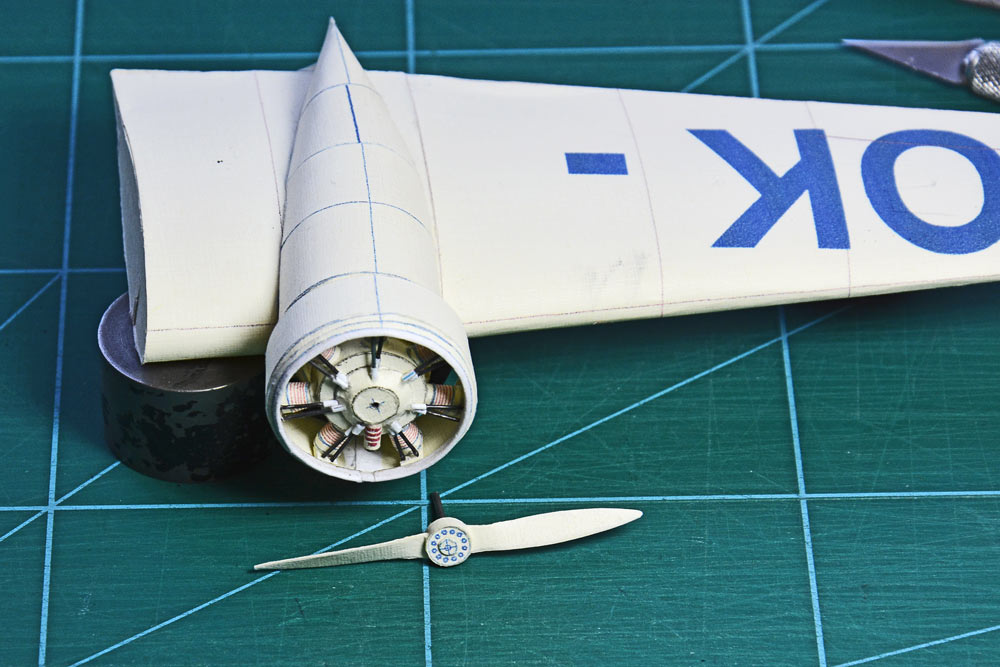

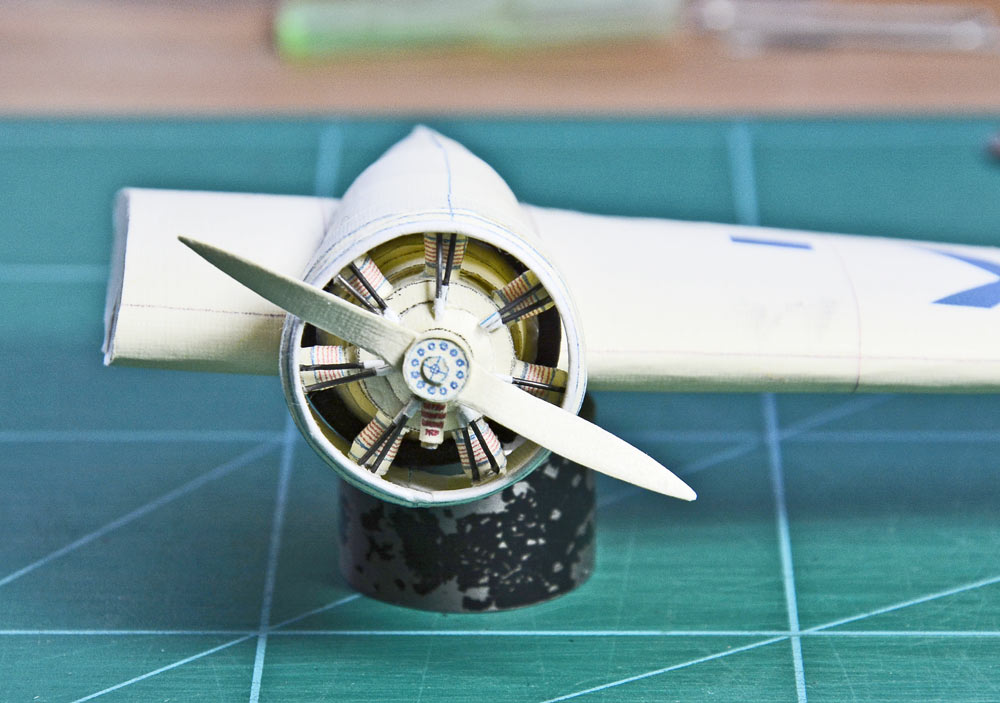

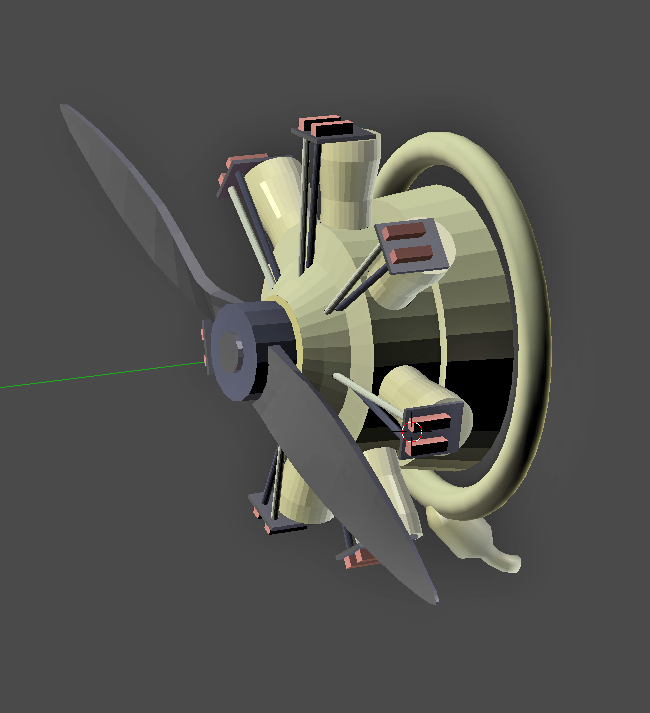

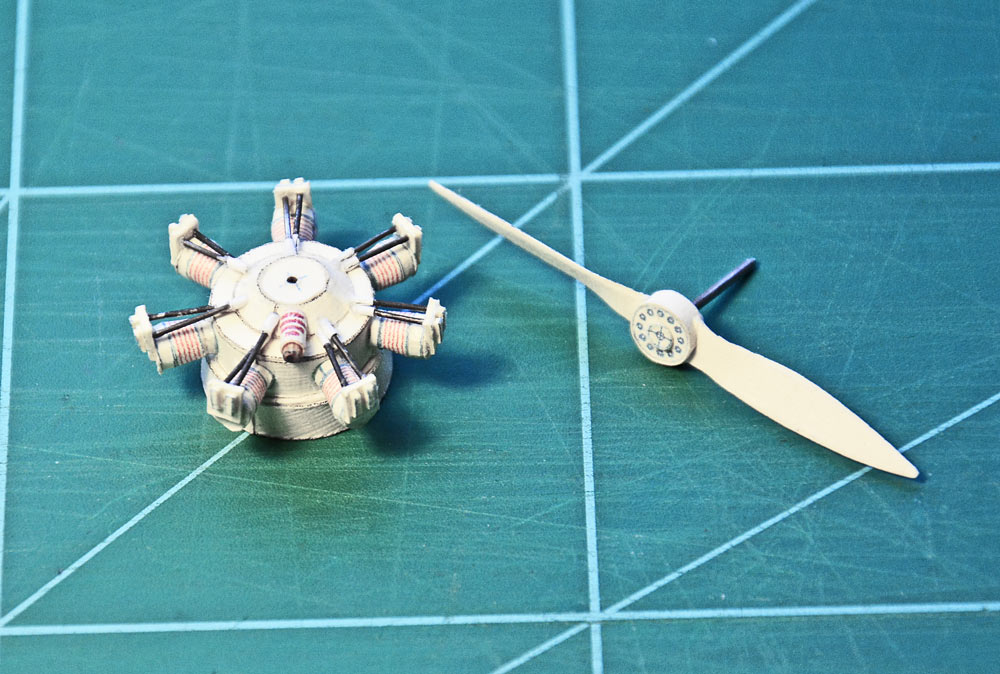

The assembly of the motors did not cause any difficulties. The shape of the motor, although complex, is easily divided into simple components. Everything is simple there.

There are many small parts to be installed on the motor. I want it to look realistic.

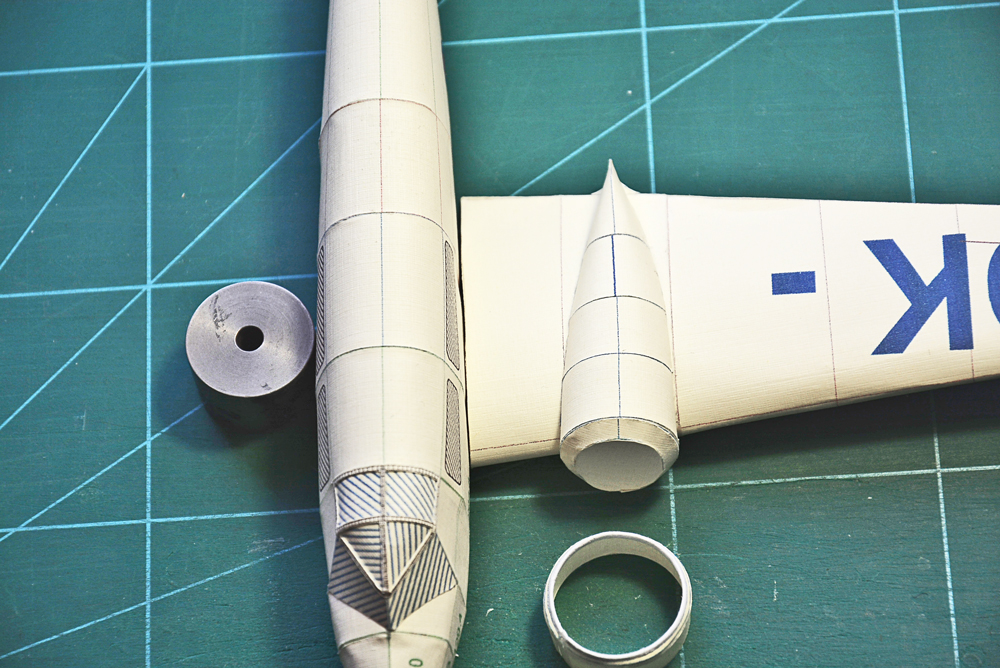

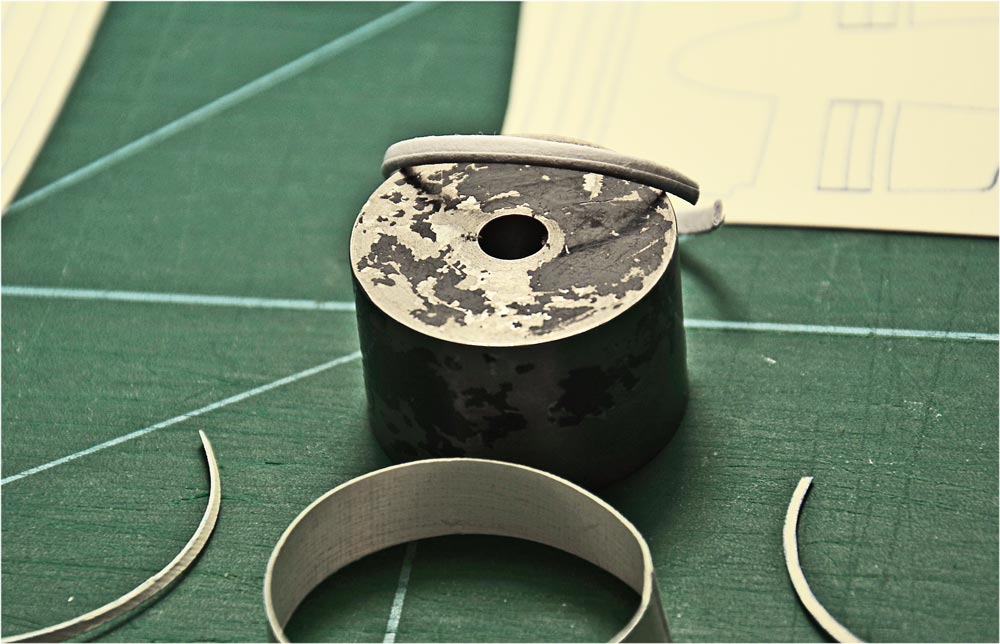

In the course of work on the engine, another question arose: how to make an annular engine exhaust pipe. It turned out that it was not difficult. It is necessary to make a tube by winding it on a wire during manufacture. Then I easily bent this tube on a suitable round tube. It was a jewelry mandrel for me. An exhaust manifold is also made. It is a short, curved tube. At the end of the work, I painted these parts black.

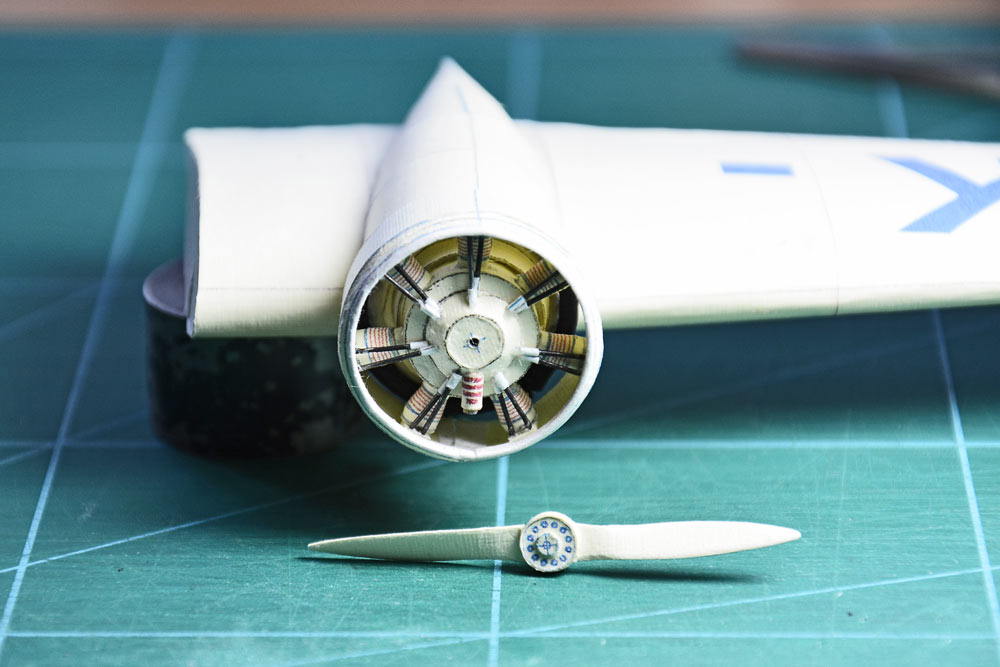

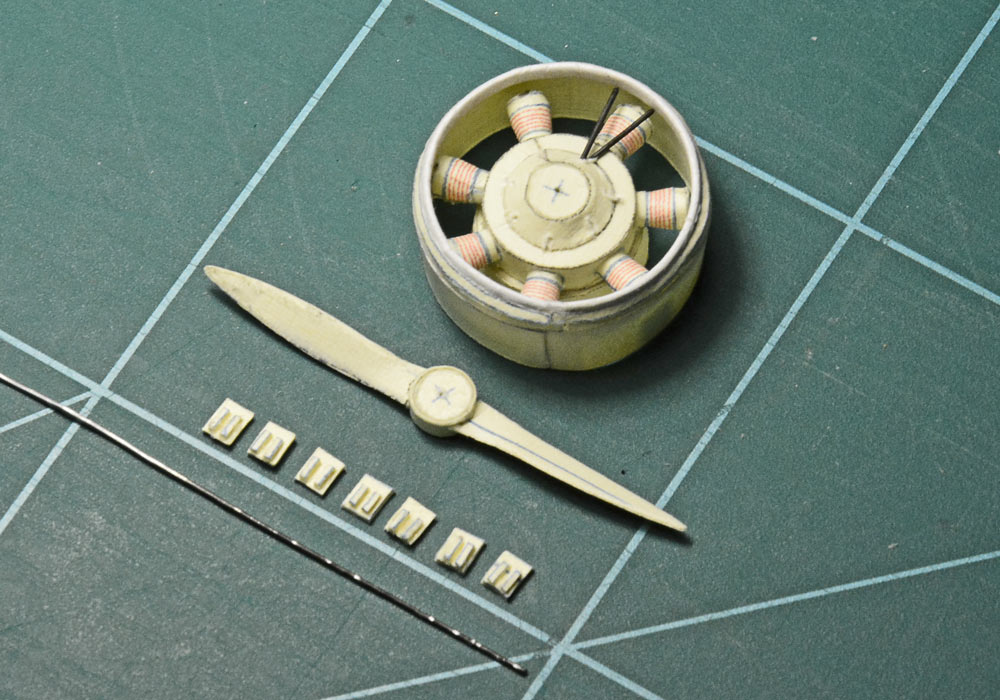

The result is a seven-cylinder aircraft engine. I gained valuable experience with the assembly technology of the unit. Outwardly, it is quite decent: there are not many difficulties, but it is also impossible to say that it is too simple. The “set” included the engine body, cylinders, connecting rods and covers over the cylinders. It looks like this:

The propeller is made as usual: hub plus blades. Be careful with the blades: the leading edge is thin and rounded. The trailing edge should come to naught. Like a real propeller. It is always sad to see the blunt and thick edges of the blades of aircraft propellers and ship propellers as well. Such a thing greatly spoils the appearance of the finished model.

The exhaust manifold is then glued to the rear of the engine. On the front frame of the engine nacelle, the engine itself must be glued to this end, with a previously glued fairing ring. Finally, glue the exhaust pipe with a muffler to the bottom of the exhaust manifold.

That’s all. It turned out like this:

The result is not perfect, but I now know how to make these details. During the final assembly of the model, I will take into account all the results obtained during the development and try to make a beautiful model.

At this point in my work, I realized that the model is too simple. This upset me at first. Then I realized that I had to look for another technology for building models. And soon I realized that it was necessary to bring the paper technology closer to the real one. Then it will be really interesting.

So I finished developing this model and moved on to the development that I am doing today. I will start to tell you about it soon.